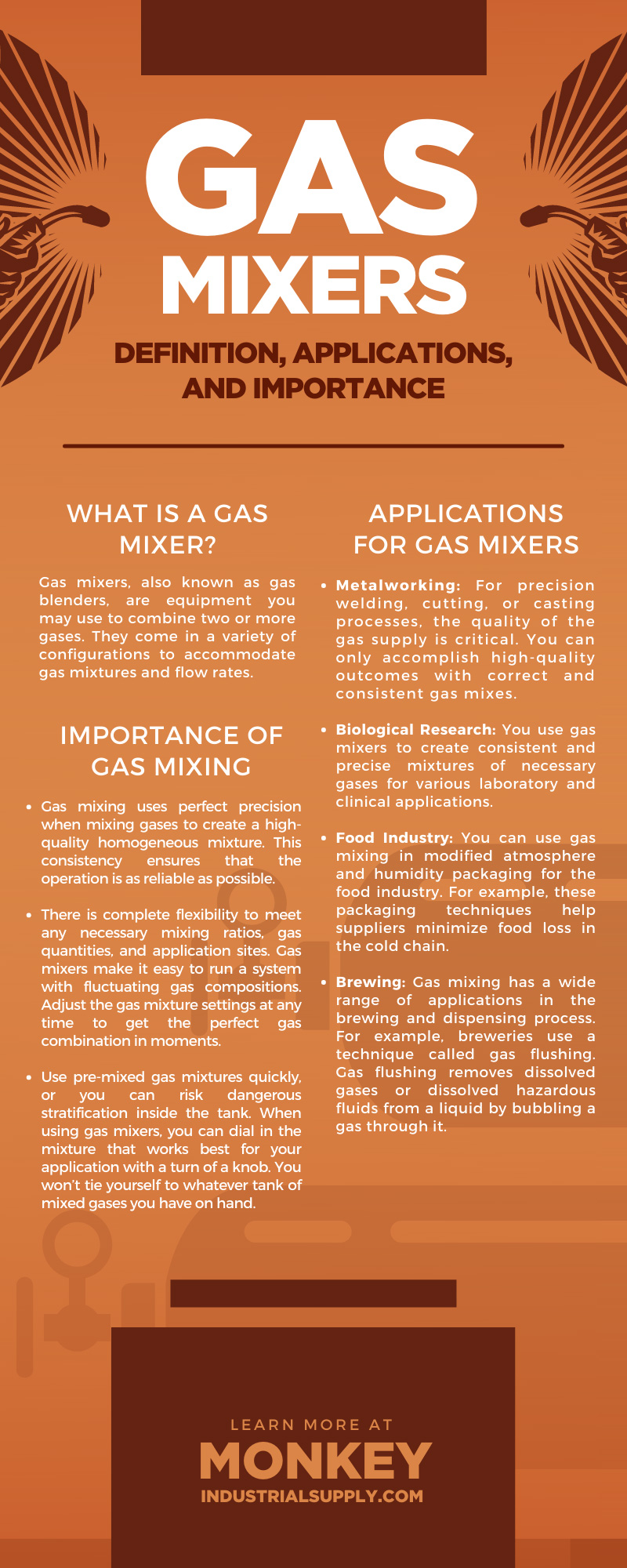

Gas Mixers: Definition, Applications, and Importance

There are many fields of business that rely on proper gas mixing for various applications. For example, in the food and beverage industries, gas mixing is used to prevent the oxidation of food. Non-air breathing gases like nitrox, trimix, and heliox are mixed and used to fill diving cylinders for Scuba divers to help them safely navigate lower depths.

Having precise, controlled gas mixtures in industrial settings is crucial for operations, such as preventing oxygen and water vapor from entering a weld location. You use gas mixers to blend two or more gases in these instances. Read on to learn more about the definition, application, and importance of gas mixers.

What Is a Gas Mixer?

Gas mixers, also known as gas blenders, are equipment you may use to combine two or more gases. They come in a variety of configurations to accommodate gas mixtures and flow rates. There are diverse gas mixing systems that have various functional operations, including the following.

Mechanical

You utilize a proportional mixing valve for 2-gas combinations. The valve features two gas inlets and mixing gas output. By rotating the valve to generate the appropriate gas combination, you can regulate the flow rates of the gases in an interplay of orifices and pistons. Individual mixing valves are used instead of proportional valves when mixes of three or more gases are required. After that, you use a mechanical mixing valve to determine the flow rate of each gas independently.

Depending on the application, gas mixers with mechanical mixing valves are used for uninterrupted or sporadic removal when attached to a gas tank. They’re incredibly durable and require very little upkeep. Expansion parts, such as gas analysis modules or an intake pressure monitor with alarm features, are available options for the systems.

Mass Flow

Gas mixers with mass flow controllers produce precise gas mixes. You will utilize this type of mixer when you require highly exact gas mixes, such as fuel gases and oxygen. The mass flow regulation technique manages disruption factors, such as temperature and pressure fluctuations while keeping a steady mixing ratio.

Surge Tank

Large storage systems provide gases that flow into a gas mixer down the line. These gases get adjusted to the same pressure level once they are inside the gas mixer. The primary gas flows via a fixed aperture ahead of the gas regulators, and the secondary gas flows through a mixture adjustment valve. Afterward, the two streams of gas come together and enter the surge tank.

Once the pressures in the tank reach the top setpoint of the switch, a solenoid (electronically controlled) valve automatically shuts off the gas supply. Whenever mixed gas is operationally needed, the pressure in the surge tank lowers until it hits the pressure switch’s lower setpoint. The gas supply is then activated, and the cycle repeats itself.

The system’s concept is that only the cycle frequency changes when the mixed gas flow rate varies. The pressure drop throughout the flow devices is homogeneous, resulting in a steady mixture.

Applications for Gas Mixers

As stated earlier, there is a wide range of applications for gas mixers across many industries.

Metalworking

For precision welding, cutting, or casting processes, the quality of the gas supply is critical. You can only accomplish high-quality outcomes with correct and consistent gas mixes. For example, you will use shielding gases in arc and tungsten arc welding to protect the weld zone from oxygen and water vapor, lowering weld quality and making welding more challenging.

Biological Research

You use gas mixers to create consistent and precise mixtures of necessary gases for various laboratory and clinical applications. One of these applications for gas mixing is developing organisms that don’t require oxygen in a reduced oxygen environment. Another application is growing cells, viruses, and other microorganisms in high-density cultures in an enriched oxygen setting.

Food Industry

You can use gas mixing in modified atmosphere and humidity packaging for the food industry. For example, these packaging techniques help suppliers minimize food loss in the cold chain. They preserve the quality of fresh produce so that you can sell it to markets far away from the growing location, extending the shelf-life. When preserving foods, a high oxygen level helps meat keep its red color, whereas a low oxygen content prevents the formation of mold on bread and vegetables.

Brewing

Gas mixing has a wide range of applications in the brewing and dispensing process. For example, breweries use a technique called gas flushing. Gas flushing removes dissolved gases or dissolved hazardous fluids from a liquid by bubbling a gas through it.

Gas mixes are also required for various types of beers to preserve the brewer’s preferred qualities. A nitrogenated beer, for example, will have a smaller CO2 volume, requiring a lower CO2 partial pressure.

Importance of Gas Mixing

Gas mixers offer many advantages to the industries that use them. Some of these benefits include the following:

- Gas mixing uses perfect precision when mixing gases to create a high-quality homogeneous mixture. This consistency ensures that the operation is as reliable as possible.

- There is complete flexibility to meet any necessary mixing ratios, gas quantities, and application sites. Gas mixers make it easy to run a system with fluctuating gas compositions. Adjust the gas mixture settings at any time to get the perfect gas combination in moments.

- Use pre-mixed gas mixtures quickly, or you can risk dangerous stratification inside the tank. When using gas mixers, you can dial in the mixture that works best for your application with a turn of a knob. You won’t tie yourself to whatever tank of mixed gases you have on hand.

We hope this guide has shed some light on gas mixers: definition, application, and importance. Monkey Industrial Supply has you covered when you need a high-quality gas mixing system of low, medium, and industrial flow. Because we place a premium on customer satisfaction, we only stock products from reputable and trustworthy manufacturers. Our experts are ready to answer any questions you may have about our products, so don’t hesitate to reach out to us today.