Welding Fumes: A Guide To the Dangers and Solutions

Many industries utilize welding heavily in their daily operations, such as aerospace, construction, and automotive manufacturing. Many individuals, such as hobbyists and artists, work with metals and other materials requiring welding. It is vital for the individuals performing these jobs to protect themselves and stay safe from some of the risks that occur when fusing metals and working with open flames.

One of the common hazards that can occur is the generation of welding fumes. These fumes can be highly hazardous to your health and can lead to potential disaster if not accounted for. That is why we have created a guide to the dangers and solutions of welding fumes.

What Are Welding Fumes

The fumes that occur when someone is welding are a complex mixture of minute particles and airborne gases. The mixture's makeup is dependent on the welding process and the materials being welded. This mixture can include metallic oxides, silicates, and fluorides.

The fumes from when metals are heated, and vapors condense into extremely fine particulate matter past boiling. The gases that form typically contain carbon dioxide, nitrous oxide, carbon monoxide, ozone, and many other potentially toxic elements.

Different Compositions in Welding

The exact fumes will differ depending on the metals being worked on and fused. The oxides in different metals can produce different compositions in the airborne particles, so it is crucial to keep in mind the material you are working on when taking precautions. Here are some examples of popular welding materials and their elements that can enter the air.

Flux

Flux is a material used to prevent or dissolve the formation and removal of oxides and other harmful contaminants. During the soldering phase of the flux, the molten soldering metal melts into a fluid slag. When cooling, the slag is hardened and must be cleaned and shaved away from the workpiece. Silicium or fluoride-containing fluxes emit amorphous silica, metal silicate, and fluoride gases.

Low-Carbon Steel

Low-carbon steel, also known as mild steel, is an alloy with a low carbon proportion of 0.3 or less. In manufacturing, it is prevalent because it is cheap and easy to weld relative to other steel alloys. Low-carbon steel fumes primarily contain iron with trace amounts of additive metals such as nickel, cobalt, copper, and manganese.

Nickel Alloy

Nickel is a comparatively straightforward metal to work with when welding. It's face-centered cubic and doesn't go through any phase changes when it cools from melting to room temperature, just like stainless steel.

Nickel is typically welded in its purest form. Still, it is more often mixed with other elements to form two types of alloys: solid solution reinforced alloys and precipitation-hardened alloys. Their fumes will contain higher contents of nickel and much less iron.

Stainless Steel

Stainless steel has long been known for its reliability and excellent corrosion resistance. This type of steel absorbs and retains heat exceptionally efficiently, making welding and soldering with the material more challenging than other types of metals.

Stainless steel is an iron-based alloy with varying quantities of chromium, the element responsible for stainless steel's rust resistance. The chromium level will range between 11% and 30%, with each variance having distinct chemical attributes affecting its output. Stainless steels have higher concentrations of chromium or nickel and lower amounts of iron in their fumes.

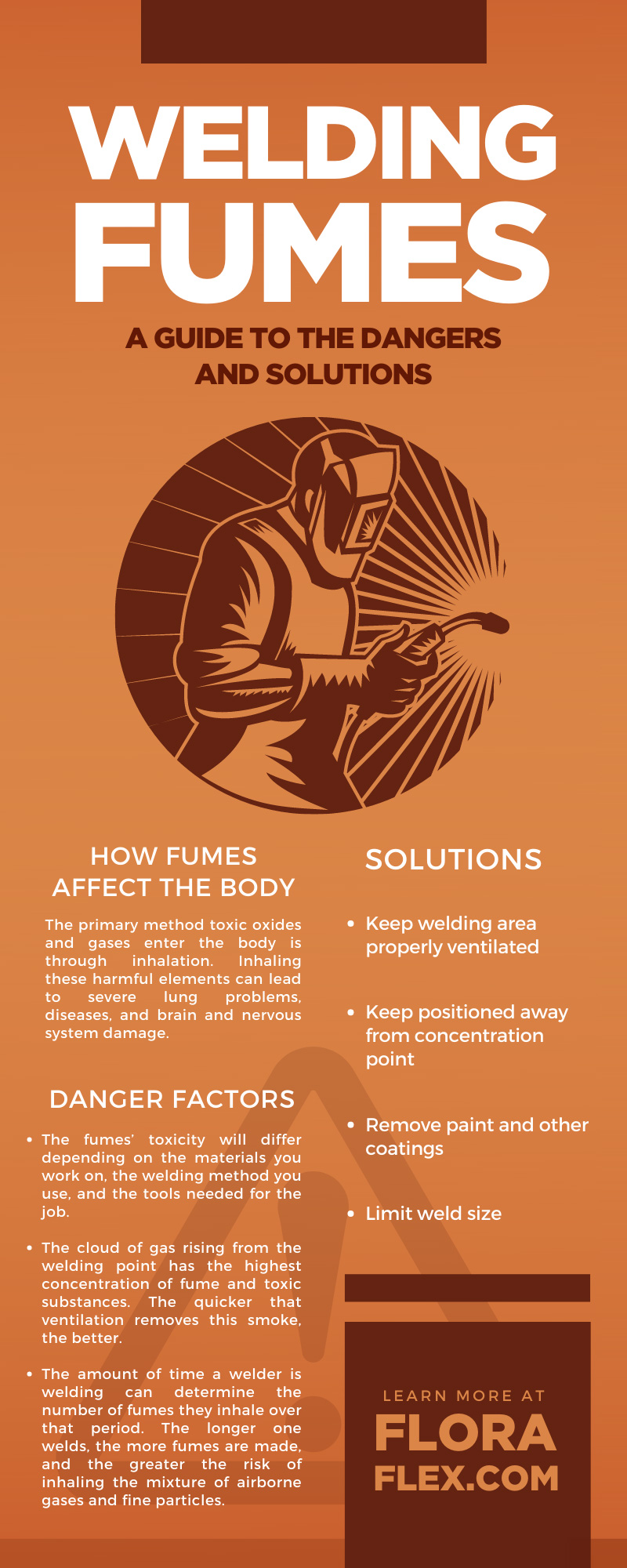

How Fumes Affect the Body

The primary method toxic oxides and gases enter the body is through inhalation. Inhaling these harmful elements can lead to severe lung problems, diseases, and brain and nervous system damage. Inflammation of the nose, sinuses, mouth, lungs, asthma, emphysema, and more severe conditions such as cancer are all common side effects of welding fume exposure.

Danger Factors

If you take no precautions and inhale fumes without protection, a few general risks occur depending on certain factors.

- The fumes’ toxicity will differ depending on the materials you work on, the welding method you use, and the tools needed for the job. The typical welding metal examples above show the variation these metals can have.

- The cloud of gas rising from the welding point has the highest concentration of fume and toxic substances. The quicker that ventilation removes this smoke, the better.

- The amount of time a welder is welding can determine the number of fumes they inhale over that period. Some fabricators only work for one or two hours a day, while others work all day. The longer one welds, the more fumes are made, and the greater the risk of inhaling the mixture of airborne gases and fine particles.

Solutions

While it may seem like there are many dangers associated with welding fumes, the truth is that rarely will a worker be exposed to these fumes without protective measures in place. There are many solutions to minimize the risk when it comes to welding fumes significantly.

Wear a Respirator

Wearing an industry-certified respirator mask is one of the most significant steps you can take to reduce the dangers when welding seriously. Weld gases and particles are filtered out of the air by respirator masks, which improve operator comfort and protection.

Keep Welding Area Properly Ventilated

Ventilation, or the free flow of fresh air, can help to minimize fume and gas levels in the workplace. Welding in open workspaces or outdoors does not ensure proper ventilation. To extract fumes and gases from the welder's breathing zone, welder's should use exhaust ventilation systems with a welding fume extraction hose attached to them.

Keep Positioned Away From Concentration Point

When you can help it, keep your face positioned as far from the fumes as possible. You can also change your body posture so that air flows from back to front, away from the breathing zone.

Remove Paint and Other Coatings

Remove any coatings and paint from the metal before welding when you can. This prevents the formation of other toxic fumes that the fusion of layers may create.

Limit Weld Size

Over-welding often produces more welding fume since the amount of weld metal used increases. An appropriately sized weld can make the least amount of welding fume compared to more extensive welds.

Welding fumes are a constant byproduct when welding occurs. Hopefully, this guide to the dangers and solutions of welding fumes can help significantly reduce the risks associated with fusing metals. Employers should stress the health and safety of their employees and do as much as possible to prevent the harmful side effects of welding fumes. Hopefully, this encourages a more proactive approach for individuals who may not typically take precautions when welding.